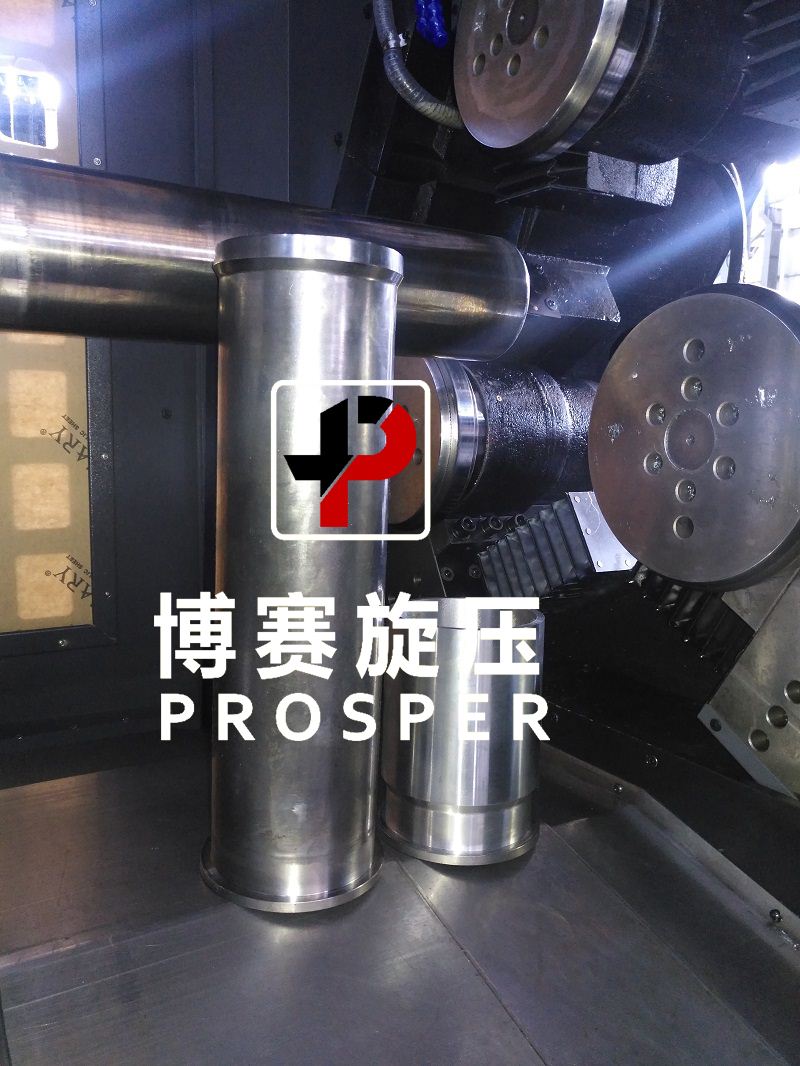

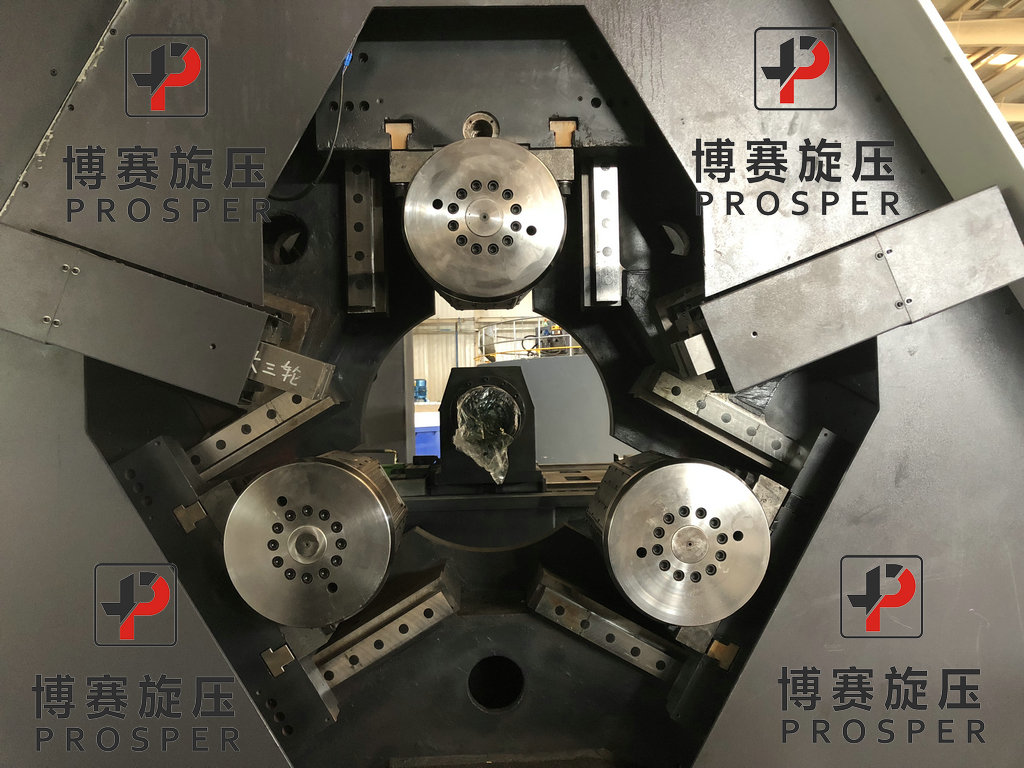

Multiple roller powerful CNC metal spinning forming Centers a powerful, can process a wide range of products, solid structure, design and manufacture precision superior spinning forming center. The mechanical structure by using 3D overall design, the machine tool body using high strength casting combination optimization, reasonable and compact structure at the same time the spinning force, the closed loop was adopted in the slipway and system designed, make the rotary pressure points and a sliding seat the most close and close loop transfer, the spinning strength greatly increased.

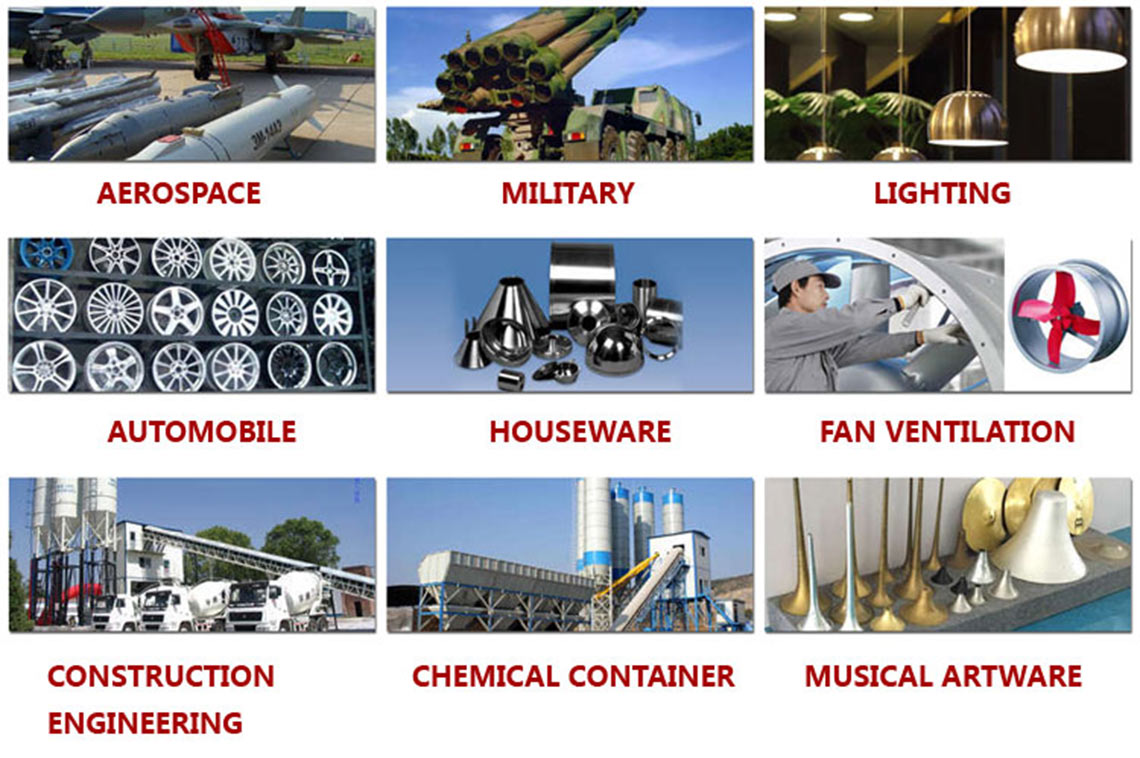

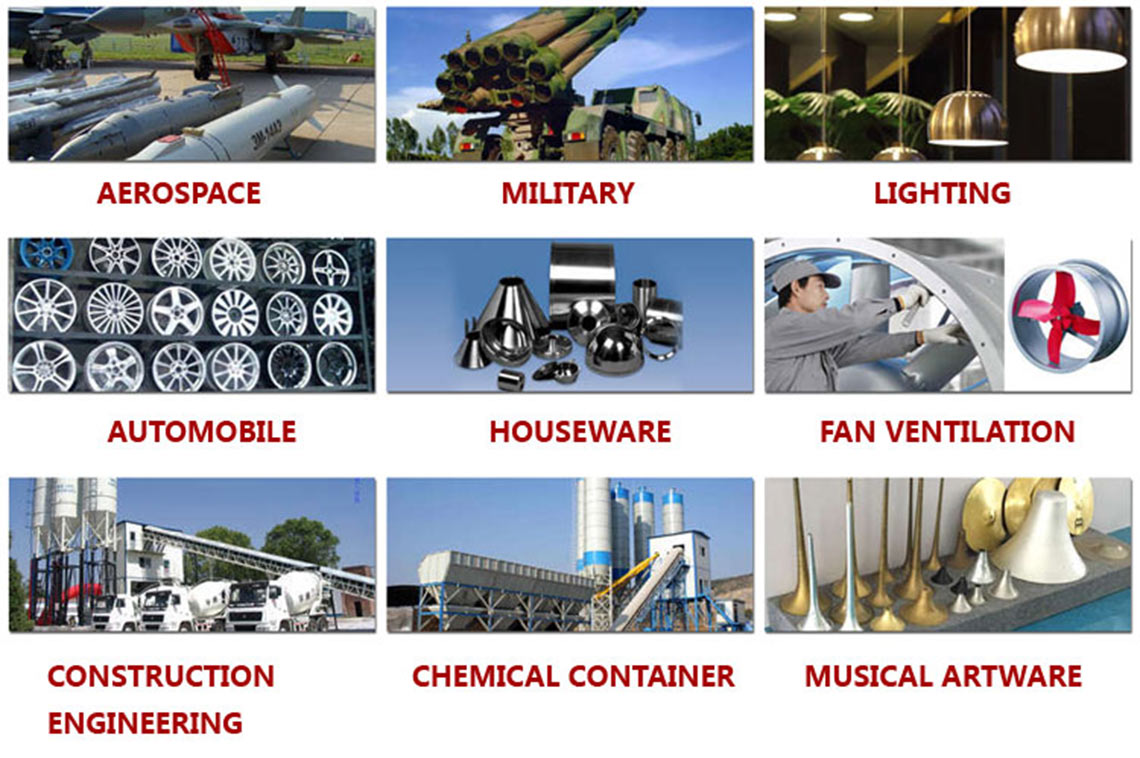

The series of CNC spinning machine industry is in wide application, can meet the needs of military, aerospace, communications, automotive, mechanical engineering, medical, environmental, fan, kitchen appliances, lighting and other industries spinning production needs. suitable for product , such as tubular, parabola, bullet shaped, cone parts production, Prosper also provide advanced, economy spinning processing scheme. with the feature of stable product quality, high production efficiency, short exchange time and lower die cost etc. in addition to the most advantage of the technology, we have strong technical service team to provide you with the most timely, high quality service.

Applications:military,spaceflighgt,avitation weapons and other manufacturing industries

three rollers power spinning

synchronizing spinning and stagger spinning

multi axises/nulti channel cnc control system

apply to carbon steel alloy steel,atainless steel,nonferrous metal and other alloy material

Technical Data:

| Parameter |

unit |

PS-CNC3X220-Z1000 |

PS-CNC3X400-Z2000 |

PS-CNC3X600-Z2500 |

PS-CNC3X800-Z5000 |

PS-CNC3X1000-Z5000 |

| Max tube diameter |

mm |

220 |

400 |

600 |

800 |

1000 |

| Max positive spinning processed length |

mm |

1000 |

2000 |

2500 |

5000 |

5000 |

| Max reverse spinning processed length |

mm |

2000 |

4000 |

5000 |

8000 |

10000 |

| Max transverse stroke (3*X axis) |

mm |

110 |

180 |

280 |

330 |

350 |

| Max transverse X axis force |

Kn |

100-300*3 |

200-400*3 |

300-500*3 |

300-600*3 |

300-600*3 |

| Max longitudinal stroke(Z axis) |

mm |

1000 |

2000 |

2500 |

5000 |

5000 |

| Max longitudinal Z axis force |

Kn |

200 |

200-400 |

300-500 |

300-600 |

300-800 |

| Main spindle motor power |

Kw |

65-155 |

110-225 |

155-275 |

225-315 |

225-400 |

Military,Spaceflighgt,Avitation,Weapons,Other manufacturing industries

-Three rollers powerful spinning

-The synchronizing spinning and stagger spinning

-The multi axises/nulti channel cnc control system

Material: Apply to carbon steel alloy steel,atainless steel,nonferrous metal ,other alloy material

About Prosper

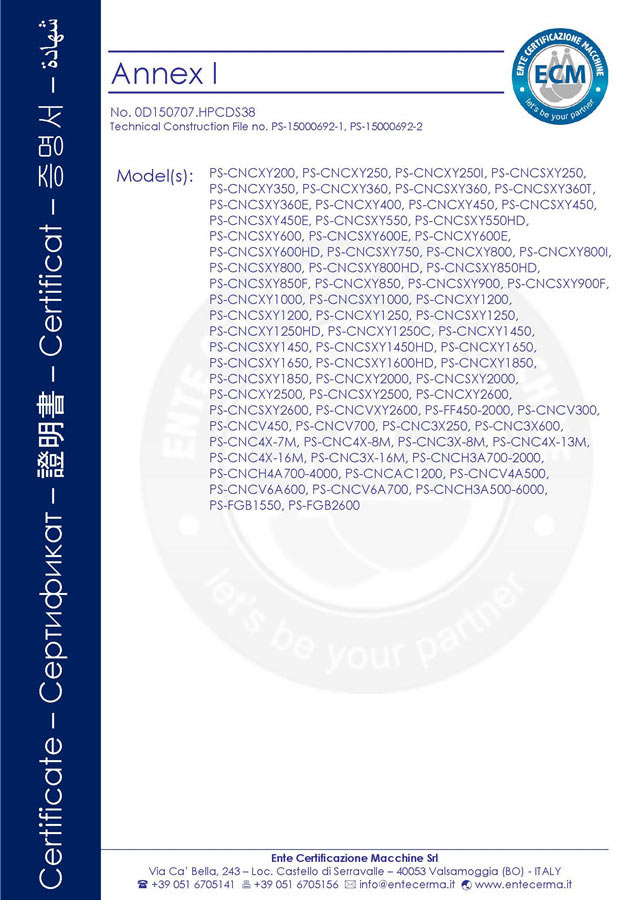

GuangDong Prosper CNC Machine Co.,Ltd is an enterprise of industrialization of new high technology which integrates research center,manufacturing,sales,customer service,and education and training school.After almost 20 years development,Prosper has nowadays owned a fifty thousand square meters operation site.Prosper values the quality of our products and services. We endeavor to provide the products and services of the most competitive advantage to our customers!

Assembly shop

The technology of workshop

The spinning experience pavilion

The technology of workshop

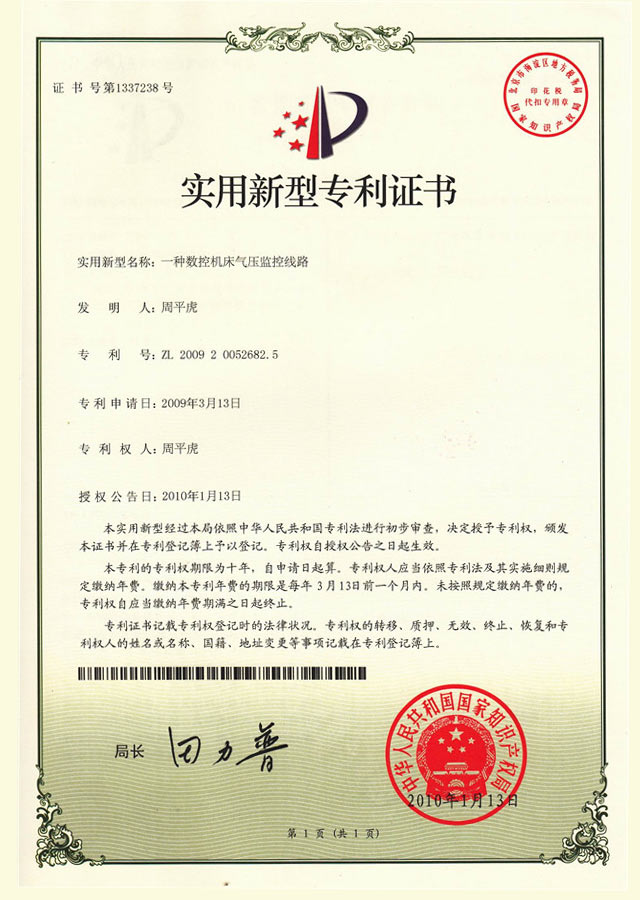

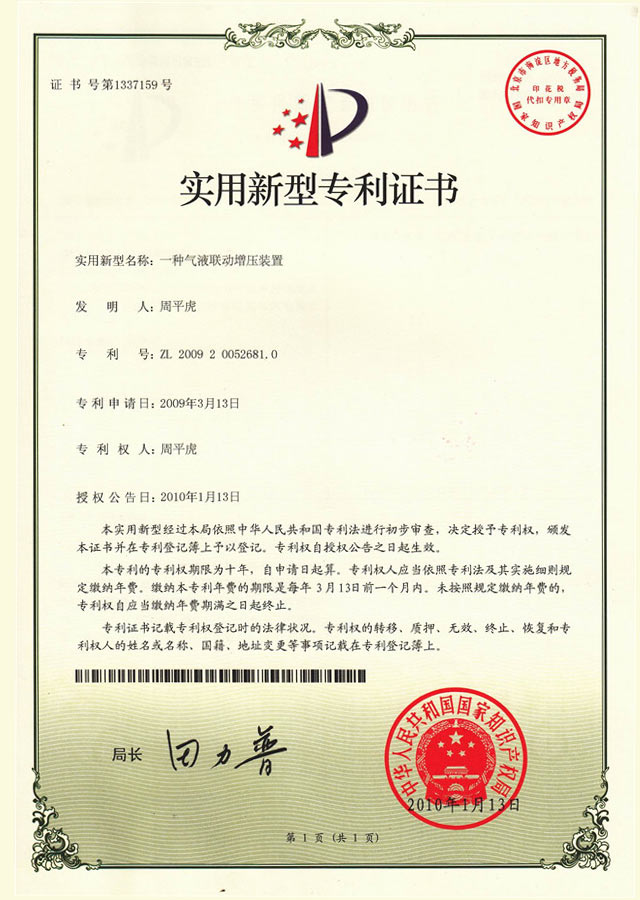

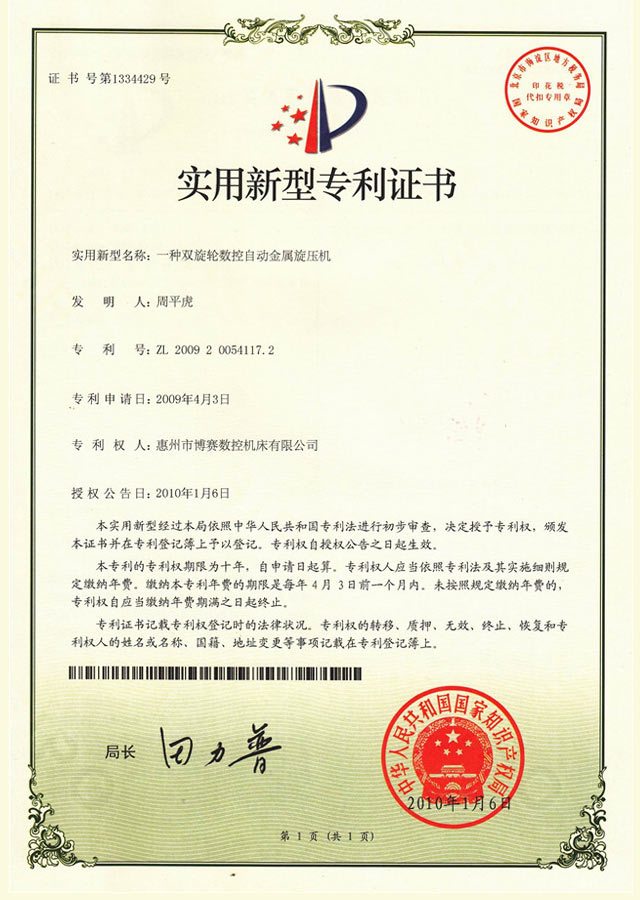

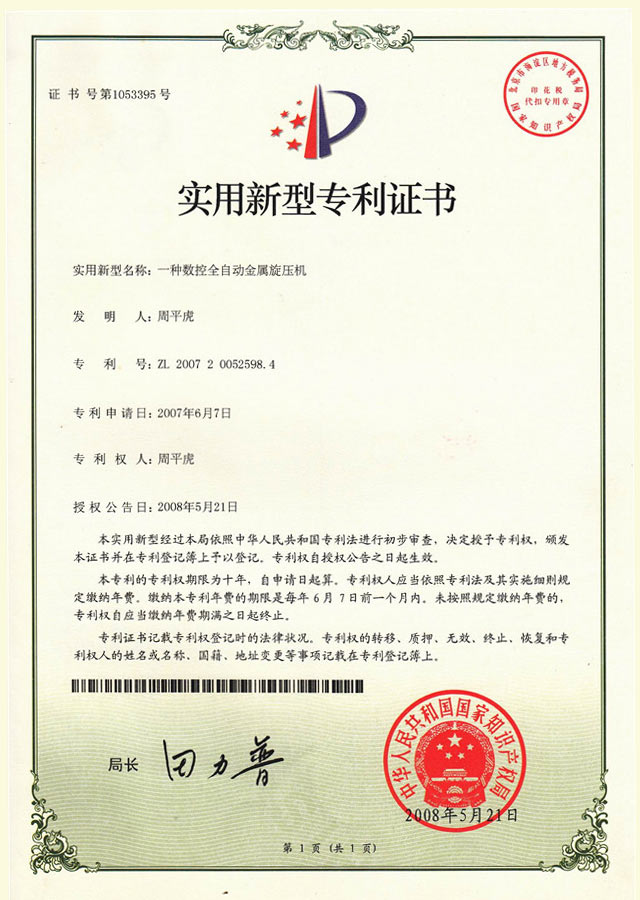

Prosper Core Technology

Application field

Cooperation strategic partner