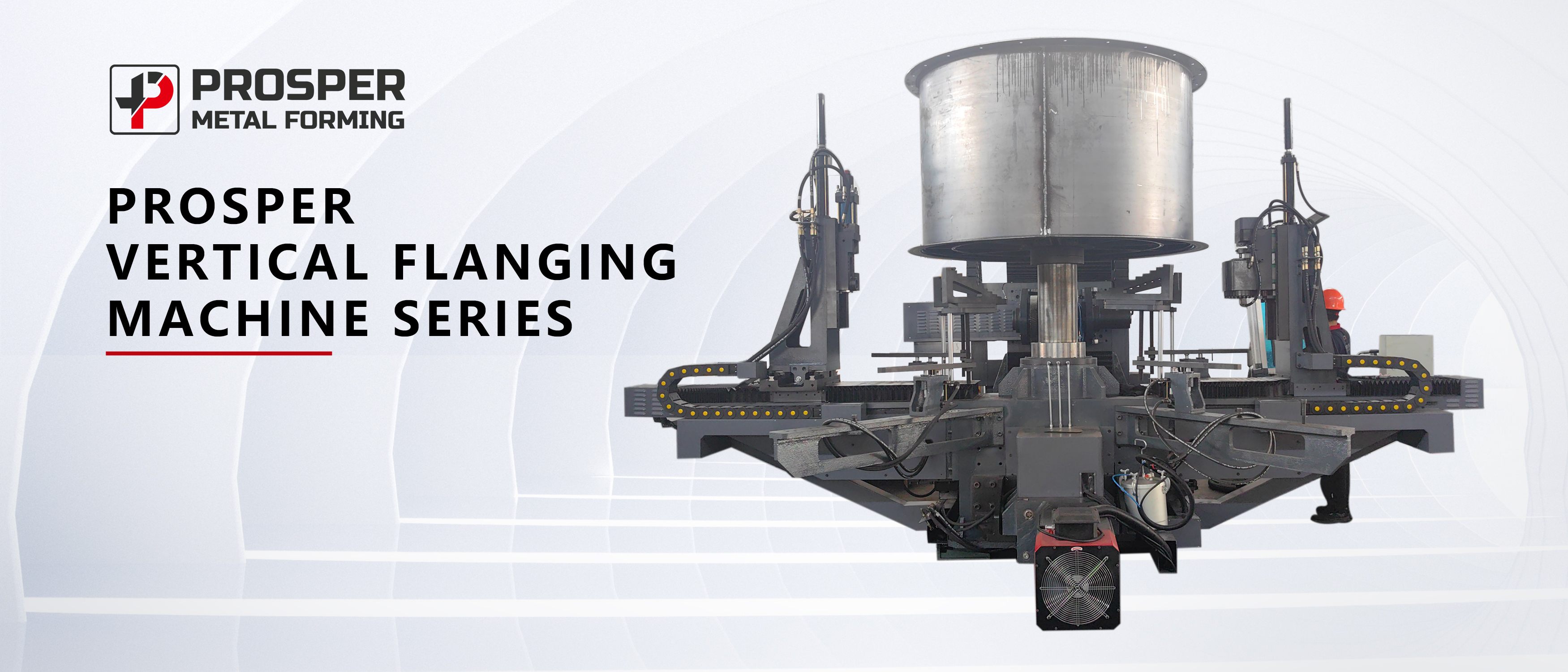

This machine is specially design for the ventilation industry. The machine is suitable for processing of the components for ventilation, modular chimneys, flanging, beading, marking of several pieces

This series of machine has resolved the problems and limitations that exist in the traditional manufacturing method, including the intense work required for manual operation, inconsistency in products, low efficiency in production and the backwardness of the production technology.

We build machines specifically designed for every specific application that our customer needs. All our machines are built after a deep analysis of the customer’s needs making possible to incorporate all the features and accessories required for every specific work.

This machine has introduced the user friendly advanced numerical program-control technology, which enables one person to control several machines at one time. It has largely reduced the cost of production and improved the efficiency and effectiveness, which is the best option for mass production of high quality production.

Technical Data:

| Model |

Bell mouth(Radius) |

Material |

Dia |

| PS-CNCFGBV1000 |

R50-100 |

Steel:3 S/S:2 |

300~1000mm |

| PS-CNCFGBV1300 |

R50-100 |

Steel:3 S/S:2 |

300~1300mm |

| PS-CNCFGBV1600 |

R50-120 |

Steel:4 S/S:3 |

300~1600mm |

| PS-CNCFGBV1800 |

R50-120 |

Steel:5 S/S:3 |

400~1800mm |

| PS-CNCFGBV2000 |

R50-150 |

Steel:6 S/S:4 |

500~2000mm |

| PS-CNCFGBV2600 |

R50-200 |

Steel:6 S/S:4 |

600~2600mm |

| PS-CNCFGBV3200 |

R50-200 |

Steel:8 S/S:5 |

800~3200mm |

| PS-CNCFGBV4200 |

R50-250 |

Steel:8 S/S:5 |

1000~4200mm |

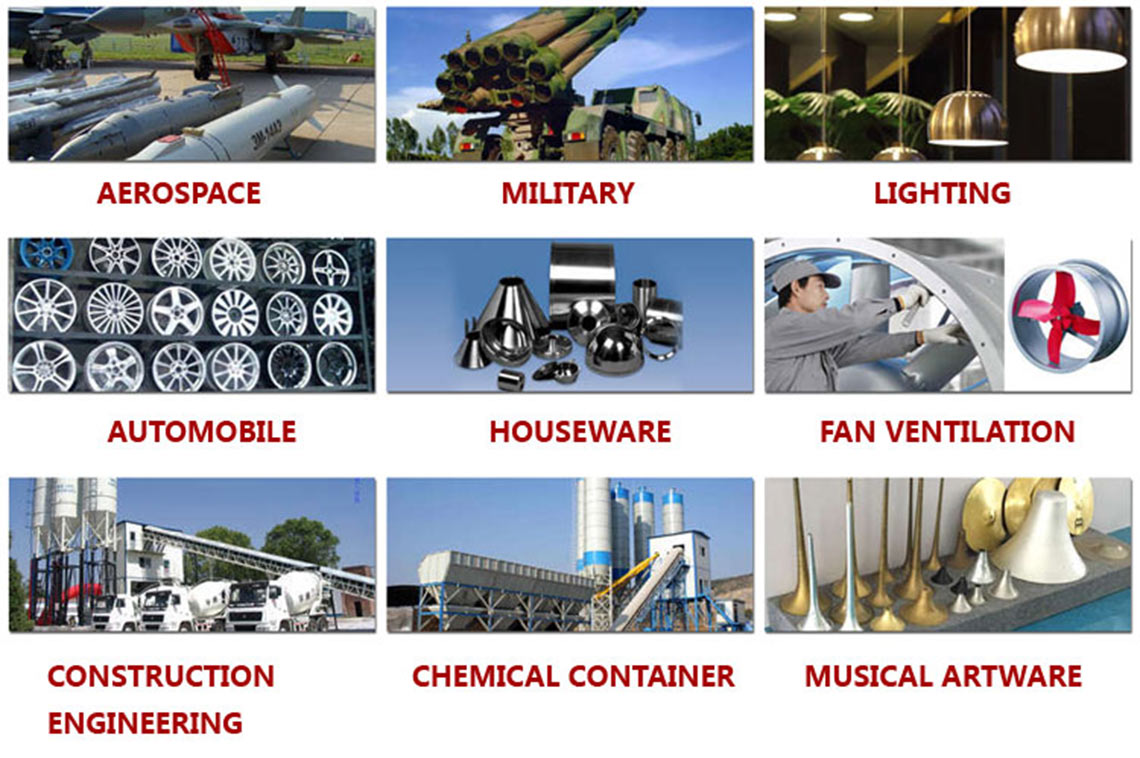

Applications:Fan and Ventilation

- 1.This series machine is specially design for the ventilation industry. The machine is suitable for processing of the components for ventilation, modular chimneys, flanging, beading, marking of several pieces.

- 2.This series of machine has resolved the problems and limitations that exist in the traditional manufacturing method, including the intense work required for manual operation, inconsistency in products, low efficiency in production and the backwardness of the production technology.

- 3.This machine has introduced the user friendly advanced numerical program-control technology, which enables one person to control several machines at one time. It has largely reduced the cost of production and improved the efficiency and effectiveness, which is the best option for mass production of high quality production.

About Prosper

GuangDong Prosper CNC Machine Co.,Ltd is an enterprise of industrialization of new high technology which integrates research center,manufacturing,sales,customer service,and education and training school.After almost 20 years development,Prosper has nowadays owned a fifty thousand square meters operation site.Prosper values the quality of our products and services. We endeavor to provide the products and services of the most competitive advantage to our customers!

Assembly shop

The technology of workshop

The spinning experience pavilion

The technology of workshop

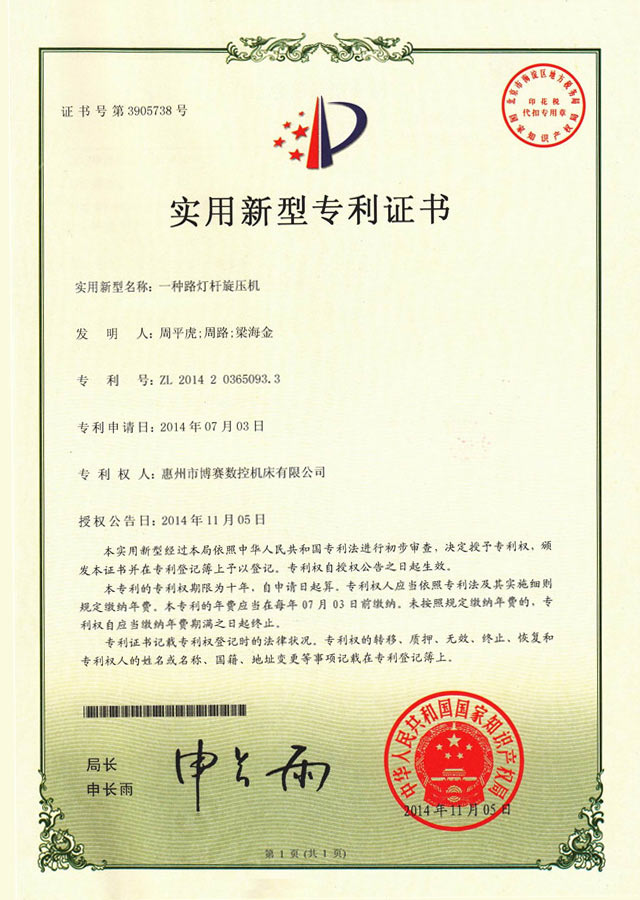

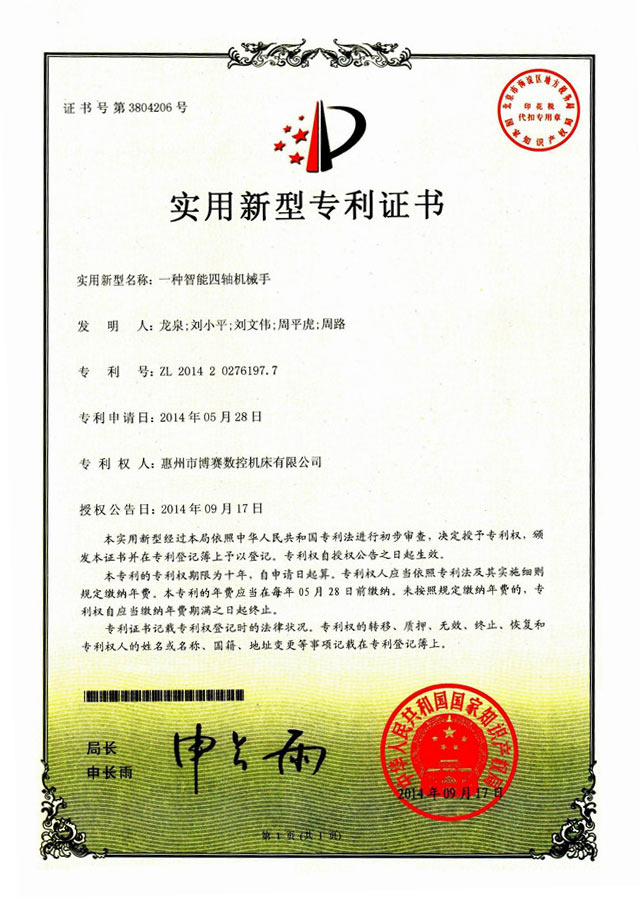

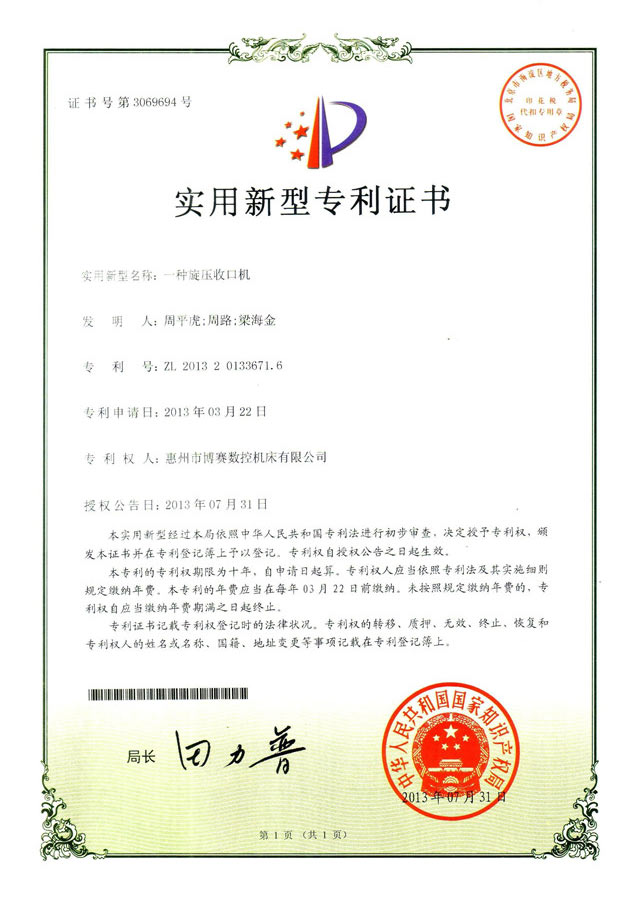

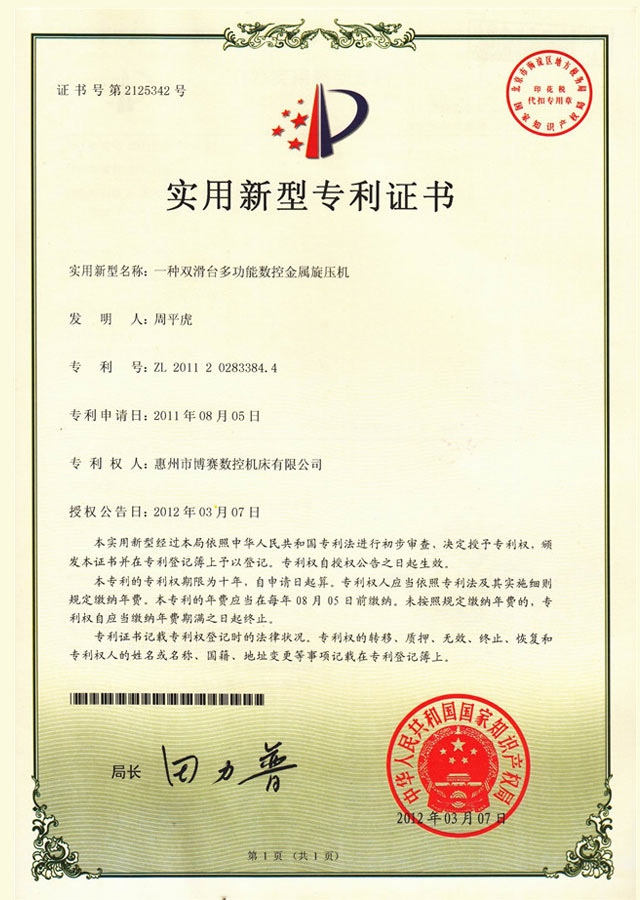

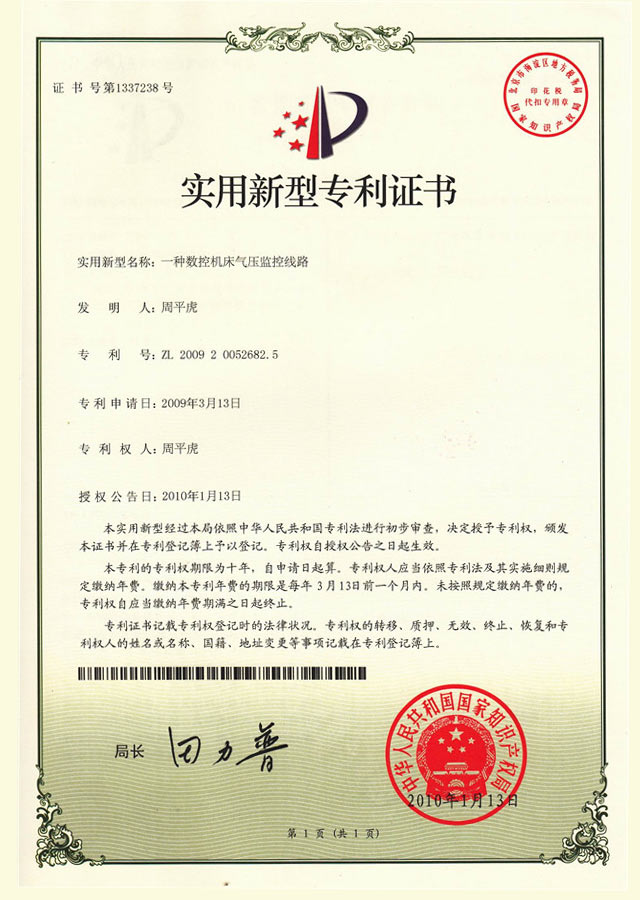

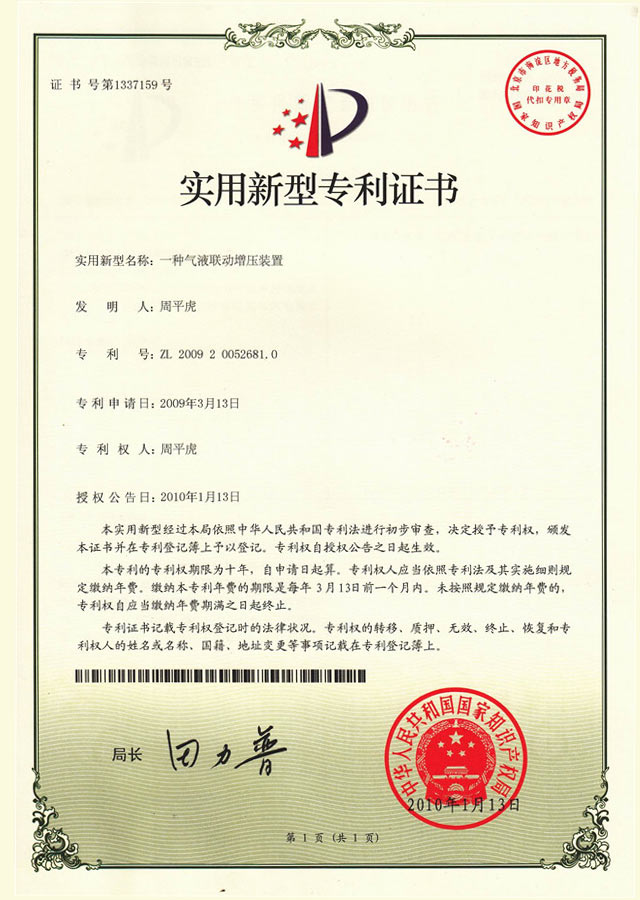

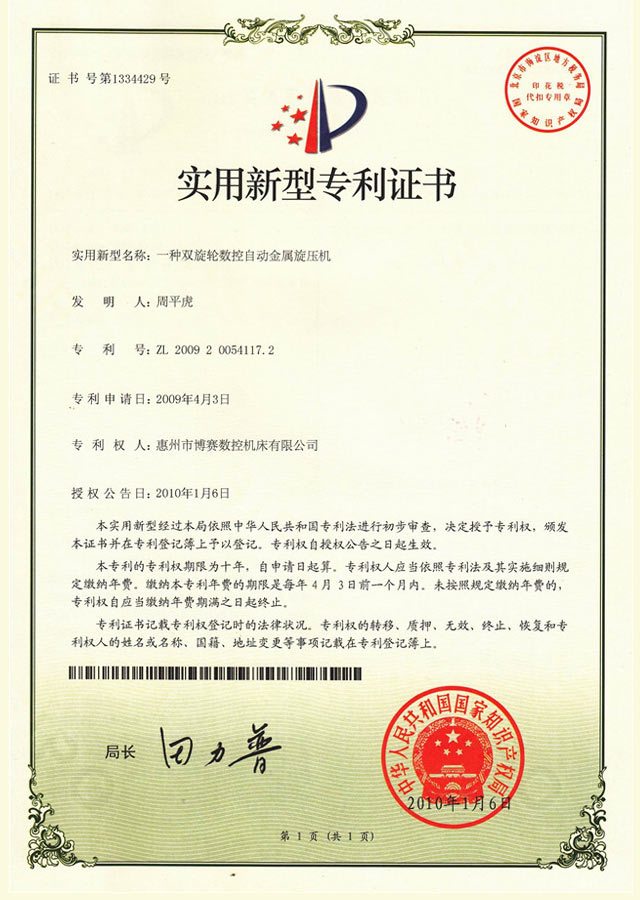

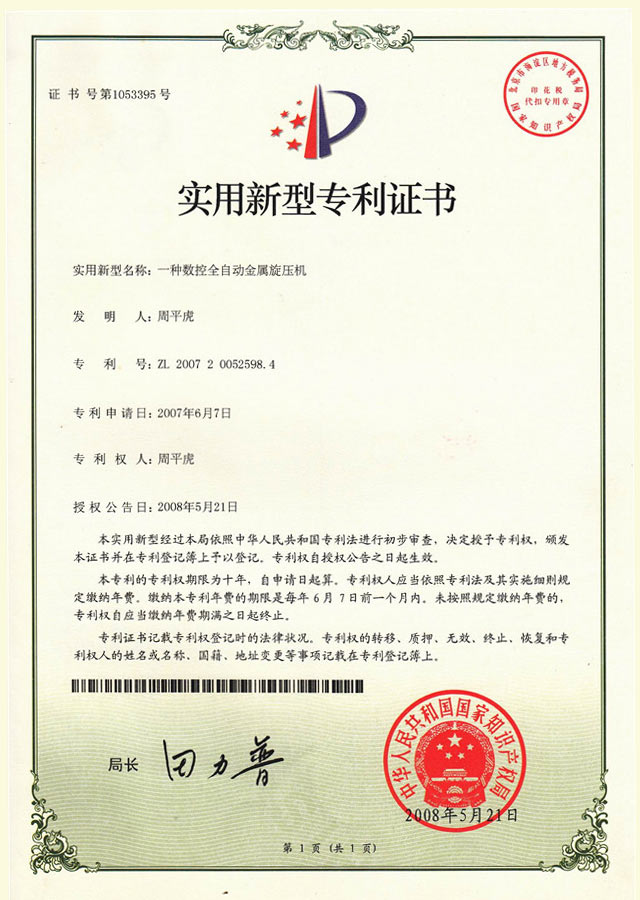

Prosper Core Technology

Application field

Cooperation strategic partner