Advantages of lighting pole series of high performance lighting/power/flag pole spinning machines:

Superior capability,high cost performance,chipless metal forming technology suitable for pole shape product spinning needs.

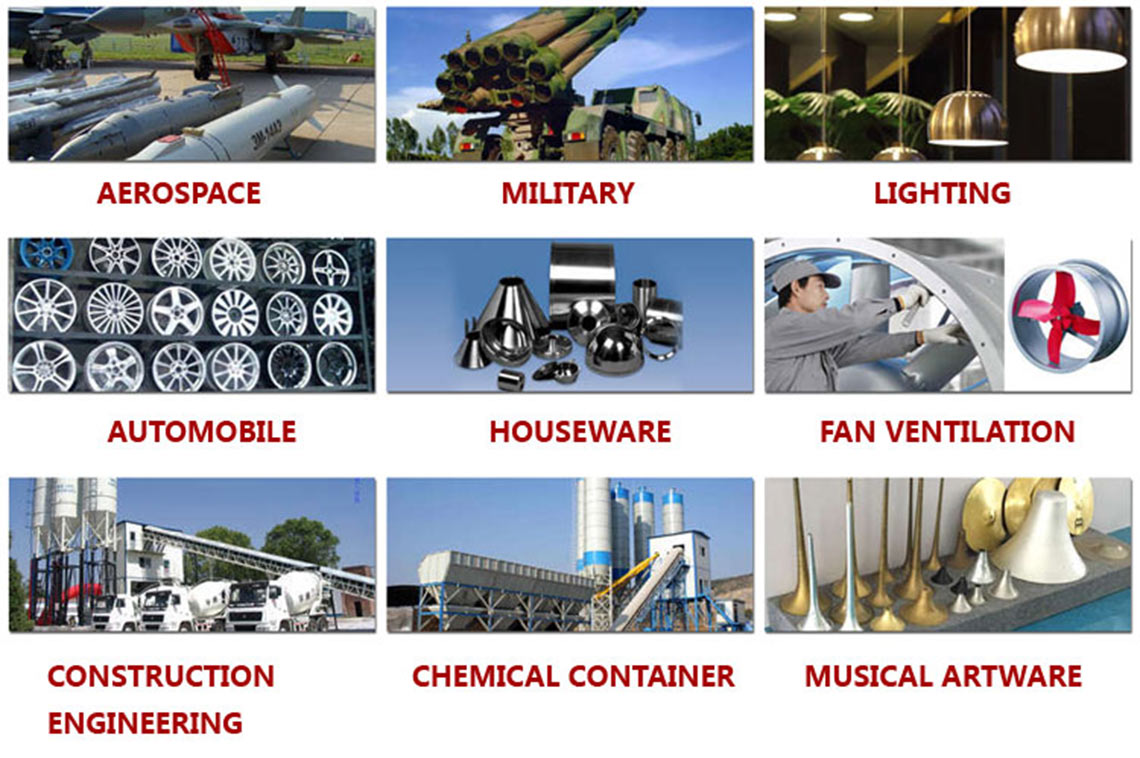

This powerful machine could be applied in a wide range of production process.It posses the firm structure high stability,exceptional design and manufacturing technology.

Equipped with the servo centering mechanism,ensured the straightness accuracy,inclination of conical surface,smoothness of products surface and accuracy of diameter.

Safe processing environment,high rate of finished products,high quality,high efficiency.

External intervened programming method controls the accuracy of specifications better;Humanized operation provides better inclusiveness for various size of products.

The pole material become firmer throught the necking down and spinning forming processes

-Product have better quality,better surface hardness and density and better smoothness.

-It uses the air spinning,necking down spinning and stretch spinning technologies,achieving a large saving of raw materials and better manufacturing efficiency and effectiveness compared to the traditional technology.

Processing range:

Advantage:

16m finished product length 2m~18m

300mm diameter 80mm~400mm

6mm thickness 2mm~8mm

Spinning technology:

Chipless spinning technology

Air closing

Stretch spinning

Planetary spinning

Heavy duty flow forming.

Technical Data:

|

Model |

unit |

Technical data |

|

Diameter |

mm |

80-300 |

|

Length |

mm |

2000-13000 |

|

Main spindle power |

KW |

65 |

|

Main spindle RPM |

rpm |

0-600 |

|

Sub main spindle power |

KW |

22 |

|

Sub main spindle RPM |

rpm |

0-200 |

|

MAX hydraulic power |

Mpa |

10 |

|

Working hydraulic power |

Mpa |

5 |

|

Thickness |

MM |

2--6 |

|

Size |

MM |

32900-4780-2800 |

|

Weight |

kg |

55000

|

-

·Equipped with servo centering mechanismensured the straightness accuracyinclination of conical surfacesmoothness of product surface and accuracy of diameter.

-

·Safe processing environmenthigh rate of finished productshigh qualityhigh efficiency.

-

·External intervened programming method controls the accuracy of specitications better;Humanized operation provides better inclusiveness for various size of products.

-

·The pole materials become firmer through the necking down and spinning frocesses.

-

-Products have better qualitybetter surface hardness and density and better smoothness.

-

-It uses the air spinningnecking down spinning and stretch spinning technologiesachieving a large savings of raw materials and better manufacturing efficiency and effectiveness compared to the traditional technology.