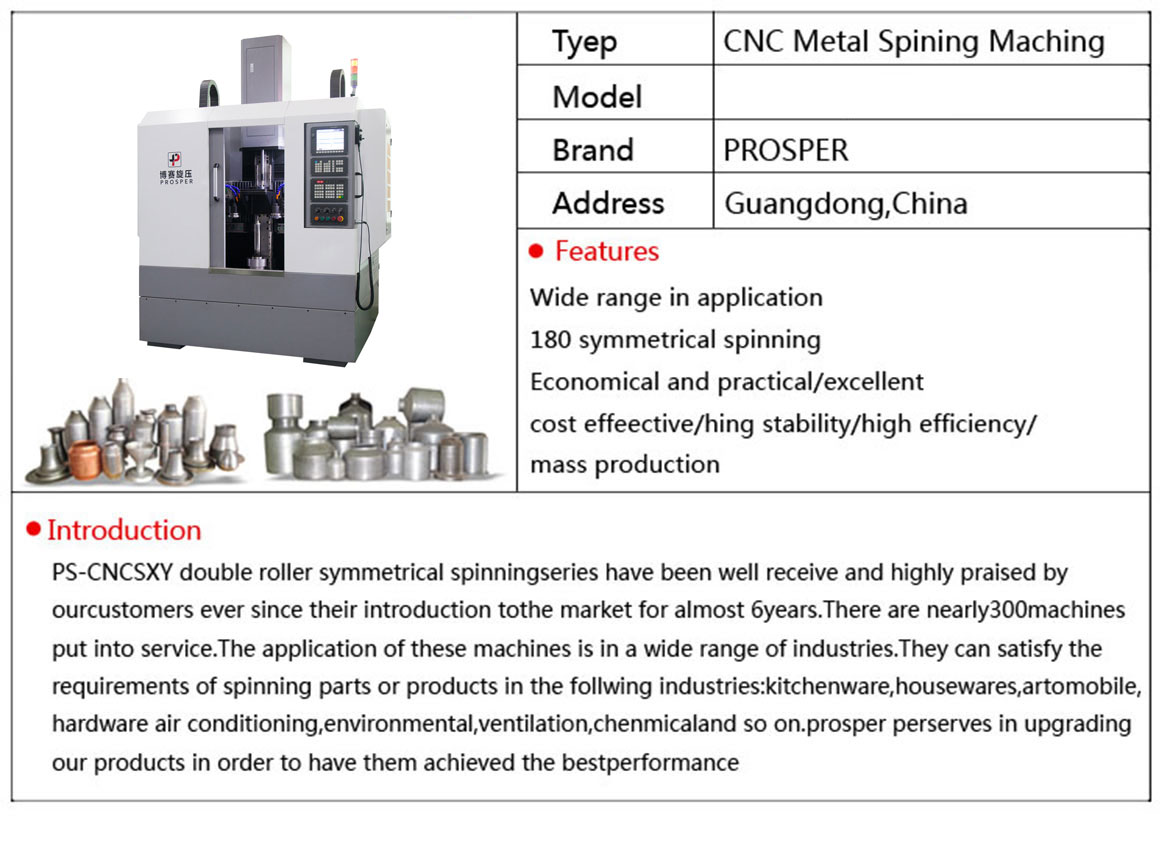

PS-CNCV160PT High Performance /High Compressive Stress Vertical Three Roller Spinning Machine is a CNC metal spinning machine specially developed for the production of small parts with strong thinning spinning and shear spinning forming. The machine has practical function, strong specialty and high production efficiency. It can complete the batch production and trial production tasks of barrel, cone, parabola, horn, warhead and other series of products, especially for thin-walled pipe fittings, barrel shaped parts and pipe fittings with variable wall thickness spinning, to meet the batch spinning production requirements of small high-quality and high-precision parts。

Technical Data:

|

SPECIFICATION: |

PS-CNCV160PT |

|

Max. Barral Shape Diameter |

40~160mm |

|

Max High of the Barral shape |

300mm |

|

Spindle size DIN 55027 |

A2-5 |

|

Main Spindle Motor (Servo spindle motor) |

5.5KW |

|

Spindle Rotational Speed (Servo spindle control) |

1200 rpm |

|

X axis travel distance |

DIA150 |

|

Z axis travel distance |

300mm |

|

Tailstock Travel |

780mm |

|

Ejector Travel |

220mm |

|

Material Clamping travel distance |

200mm |

|

Tool Turret position |

1+2 |

|

Sheet Thickness Approx (Stainless Steel ) |

0.2~0.6mm |

Applications:Lightings、metal art crafts、hardwares

Best spinning solution for small to medium diameter/thickness product

Excellent cost effective/economical practical

High Efficiency/High stability

Match With automatic material loading system

About Prosper

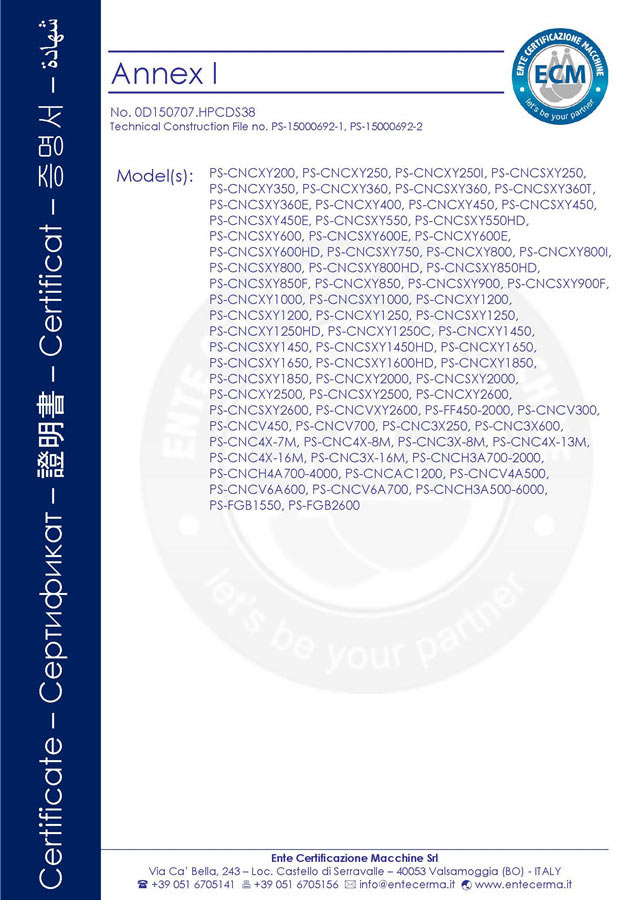

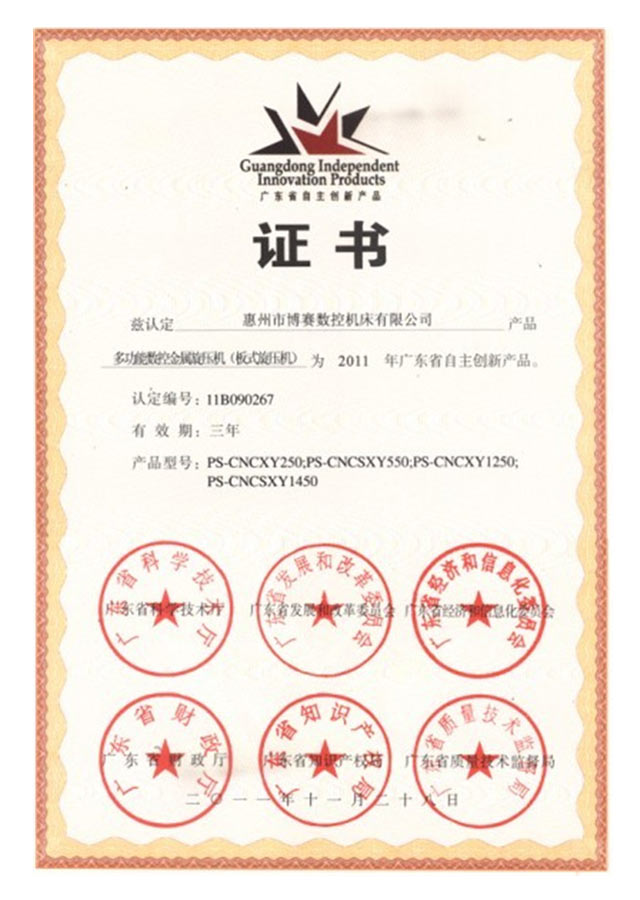

GuangDong Prosper CNC Machine Co.,Ltd is an enterprise of industrialization of new high technology which integrates research center,manufacturing,sales,customer service,and education and training school.After almost 20 years development,Prosper has nowadays owned a fifty thousand square meters operation site.Prosper values the quality of our products and services. We endeavor to provide the products and services of the most competitive advantage to our customers!

Assembly shop

The technology of workshop

The spinning experience pavilion

The technology of workshop

Prosper Core Technology