- Home

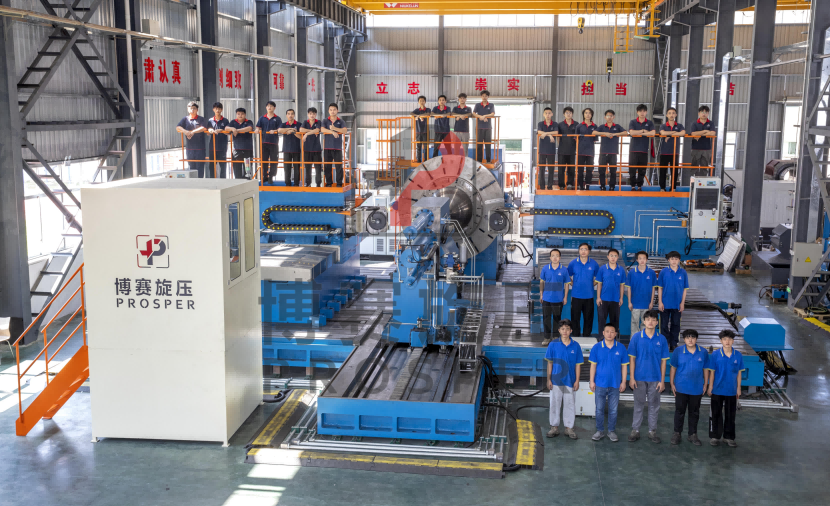

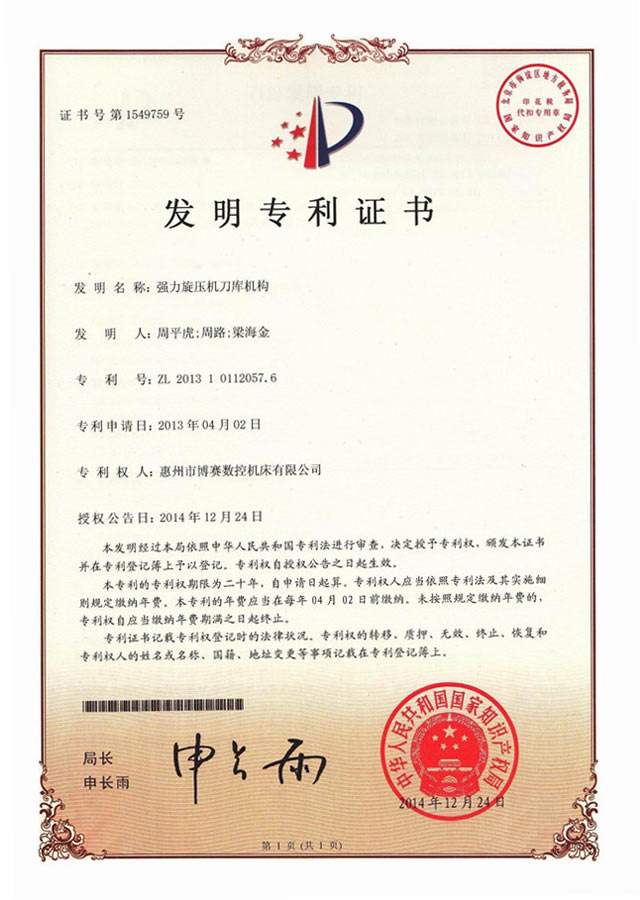

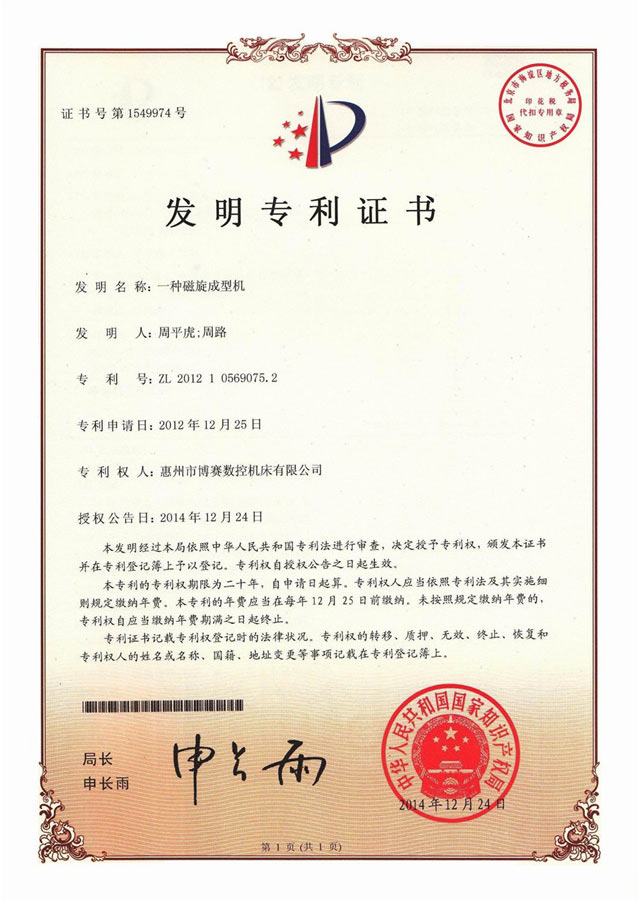

- Company

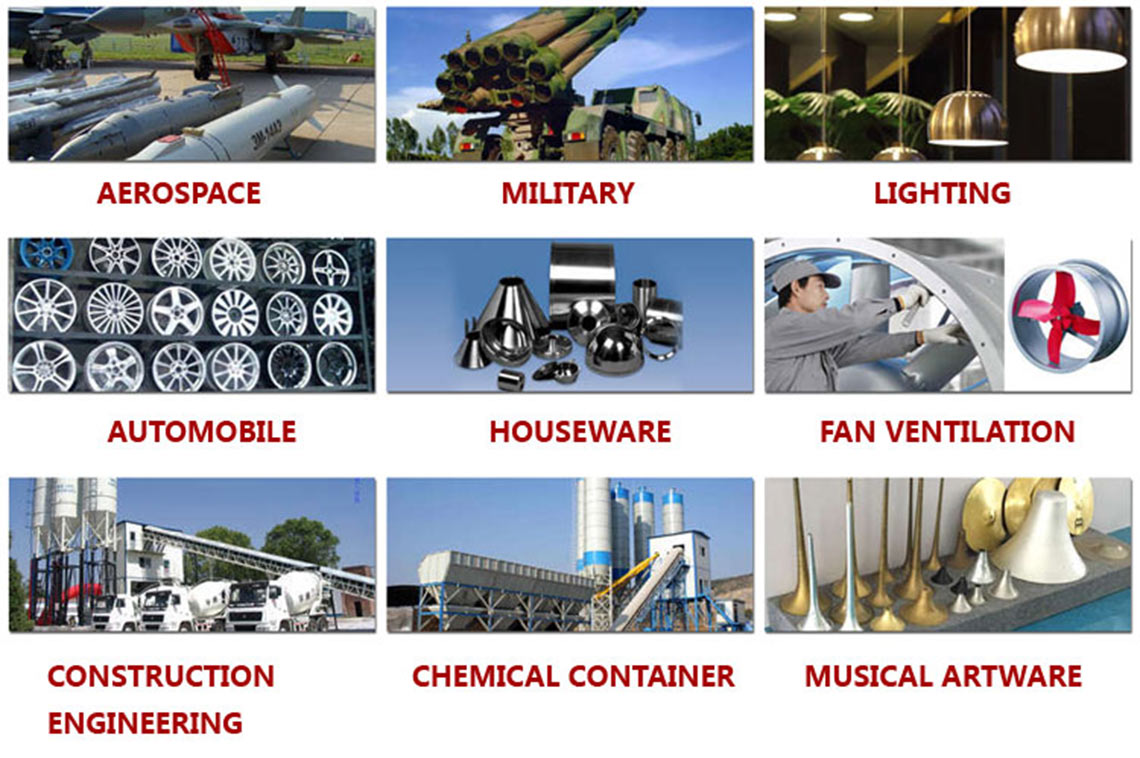

- Industries

- Technologies

- Machine&Video

- Multi-Rollers Flow Forming Machine Series

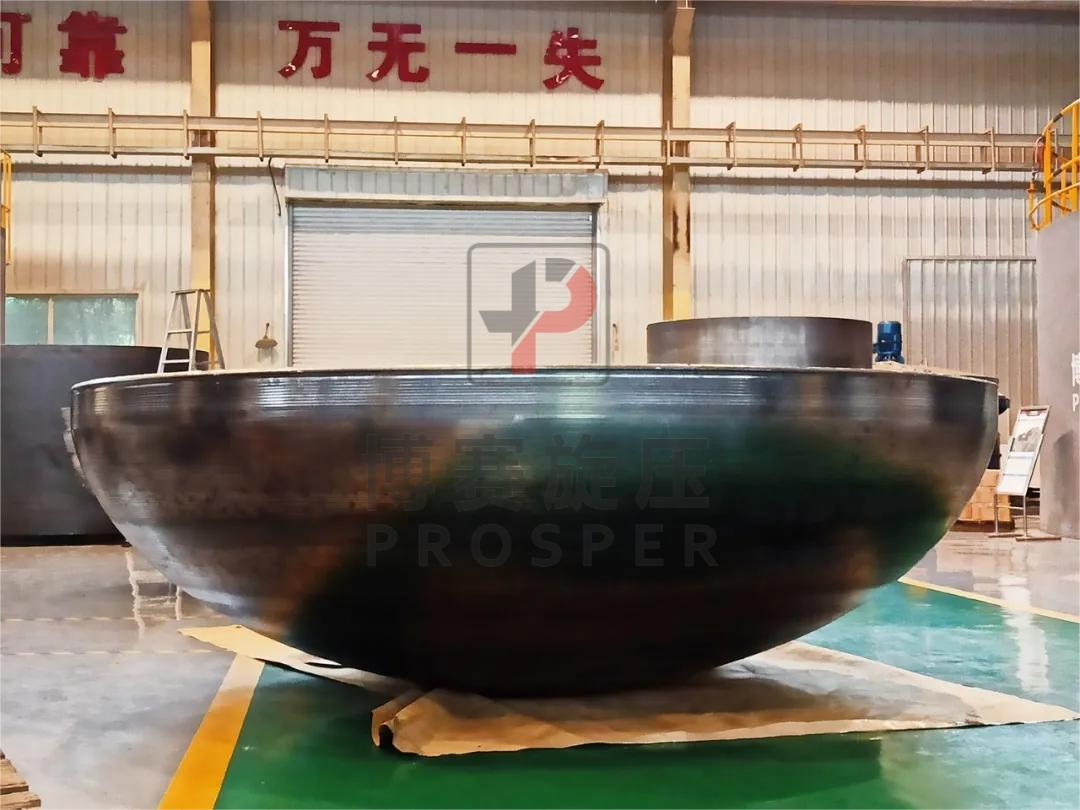

- Heavy Duty Type With Heating Double Roller CNC Metal Spinning Machine Series

- High Performance Double Arms Spinning Machine Series

- High Speed Precision Spinning Machine Series

- High Performance Vertical Spinning Machine Series

- Light Pole/flag Pole Spinning Machine Series

- Flanging & Bell-Mouth Ventilation Spinning Machine Series

- High Performance/Heavy Duty Single Roller Spinning Machine Series

- Tube/Pipe and High Pressure Gas Cylinders Spinning Machine Series

- High Performance Double Arms Spinning Forming Center Series

- High Performance/Large-Diameter CNC Spinning Machine Series

- Youtube Video

- Services

- News

- Contact